Quality isn’t just a target—It’s a Promise

At Apexline, quality is more than a target—it’s the foundation of everything we do. Every product is engineered to the highest standards and undergoes rigorous inspection using advanced technologies like CNC vision systems and certified gauges. Our ISO 9001:2015-certified quality management system ensures consistency, traceability, and continuous improvement across all processes.

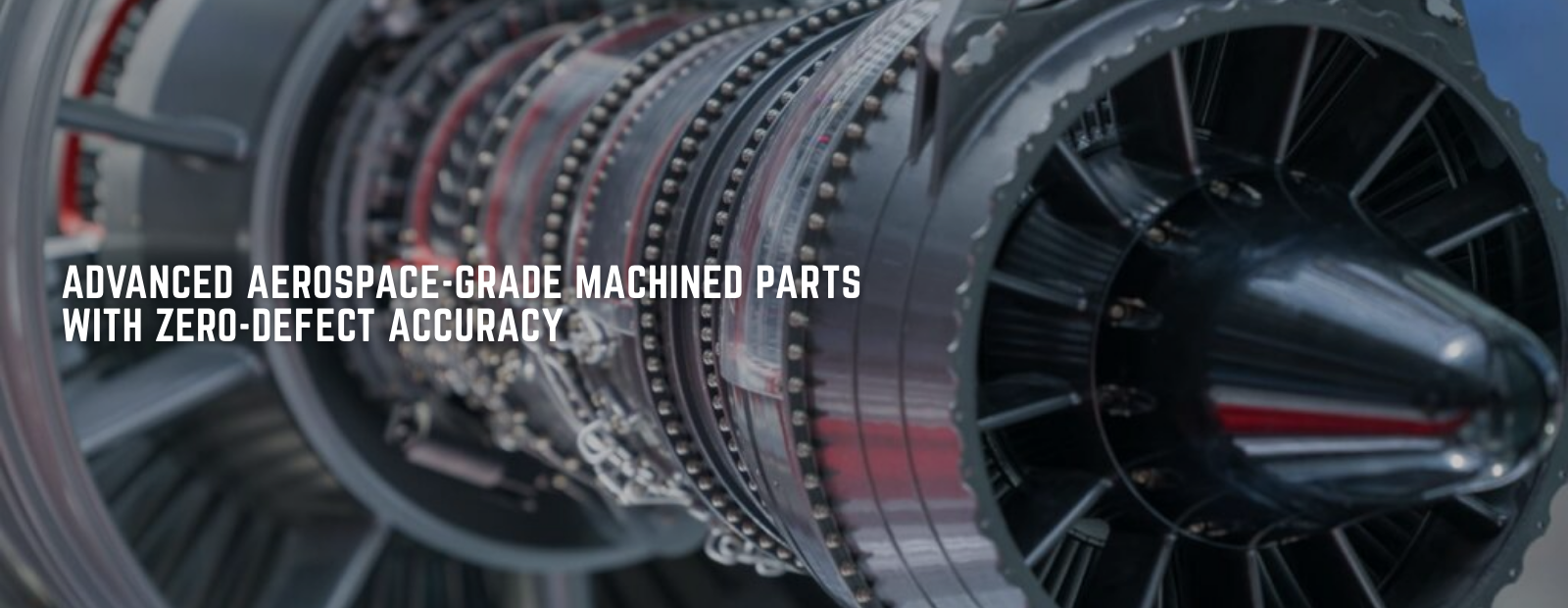

Each component is tested for precision and reliability, meeting zero-defect standards and full compliance with client specifications. Our AS9100D certification—recognized globally in aerospace—reflects our commitment to safety, defect-free manufacturing, and operational excellence.

From design to delivery, quality is built into every step. Our state-of-the-art facilities and comprehensive inspection processes guarantee flawless performance every time. With Apexline, you receive more than products—you receive a promise of excellence backed by certified standards and rigorous quality assurance. This is how we deliver enduring value and superior performance for every client.

Quality Services

Aerospace

Expert multidisciplinary engineering delivering precise, reliable, and cutting-edge solutions for the aerospace sector’s demands.

Defence

Specialized defence engineering solutions delivering precision, reliability, and mission-ready performance for critical land, air, and naval applications.

Oil & Gas

Apexline Engineering delivers expert, safe, and efficient engineering solutions tailored for the Oil & Gas industry.

Mining

Apexline Engineering provides innovative, safe, and efficient engineering solutions for the mining industry’s needs.

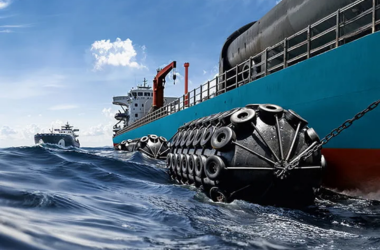

Marine

Professional marine engineering services focused on safety, efficiency, and innovation for vessel and offshore projects.

Energy Services

Specialized engineering supporting sustainable, reliable, and optimized energy projects across diverse industrial sectors.

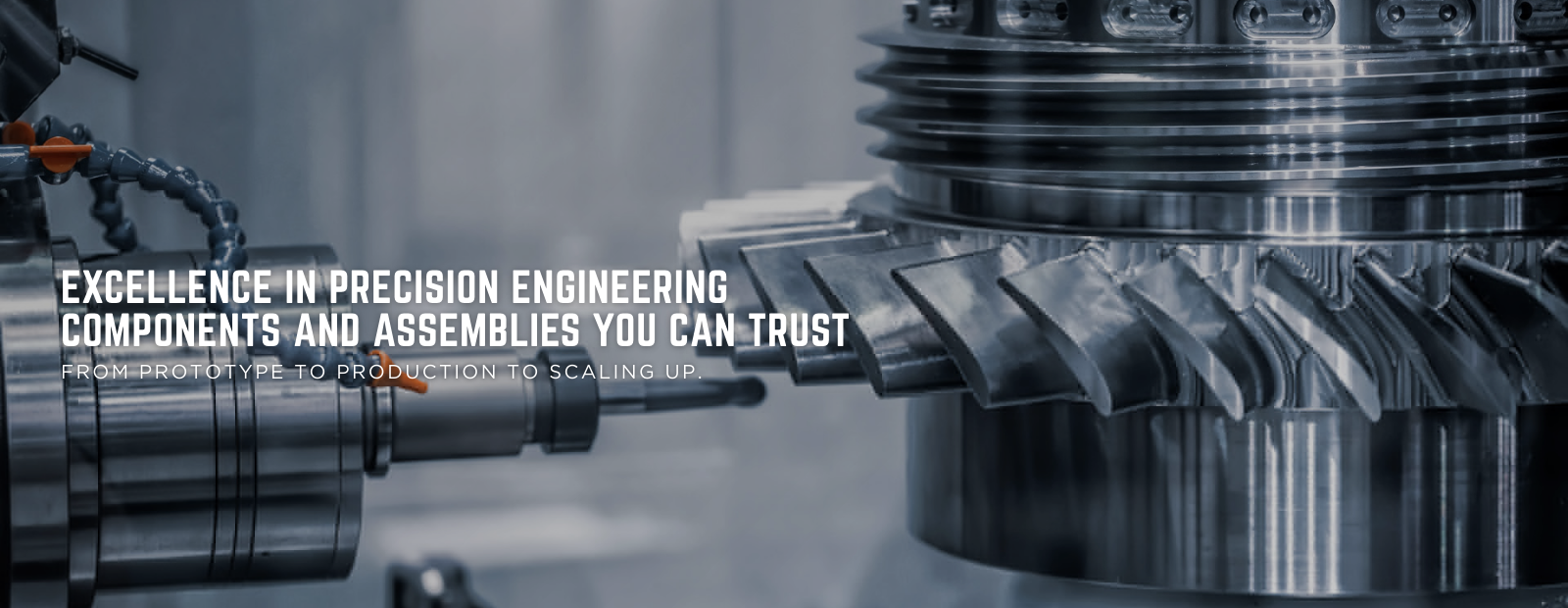

Advanced CNC Technology

At Apexline Engineering Services, we utilise state-of-the-art multi-axis and five-axis CNC machining to deliver exceptional precision. Our advanced capabilities allow us to produce highly intricate components that meet even the most demanding technical requirements.

Why Choose Apexline Engineering Services Innovative Solutions

Customized Manufacturing Solutions

Every project is different—and we treat it that way. We specialise in delivering tailored machining and engineering solutions designed around your industry-specific needs, ensuring you receive exactly what your operations demand.

Uncompromising Quality Assurance

Backed by ISO 9001:2015 certification, our quality systems ensure total reliability, complete material traceability, and strict adherence to the highest industry standards. You can trust Apexline to deliver consistent, inspection-ready parts every time.

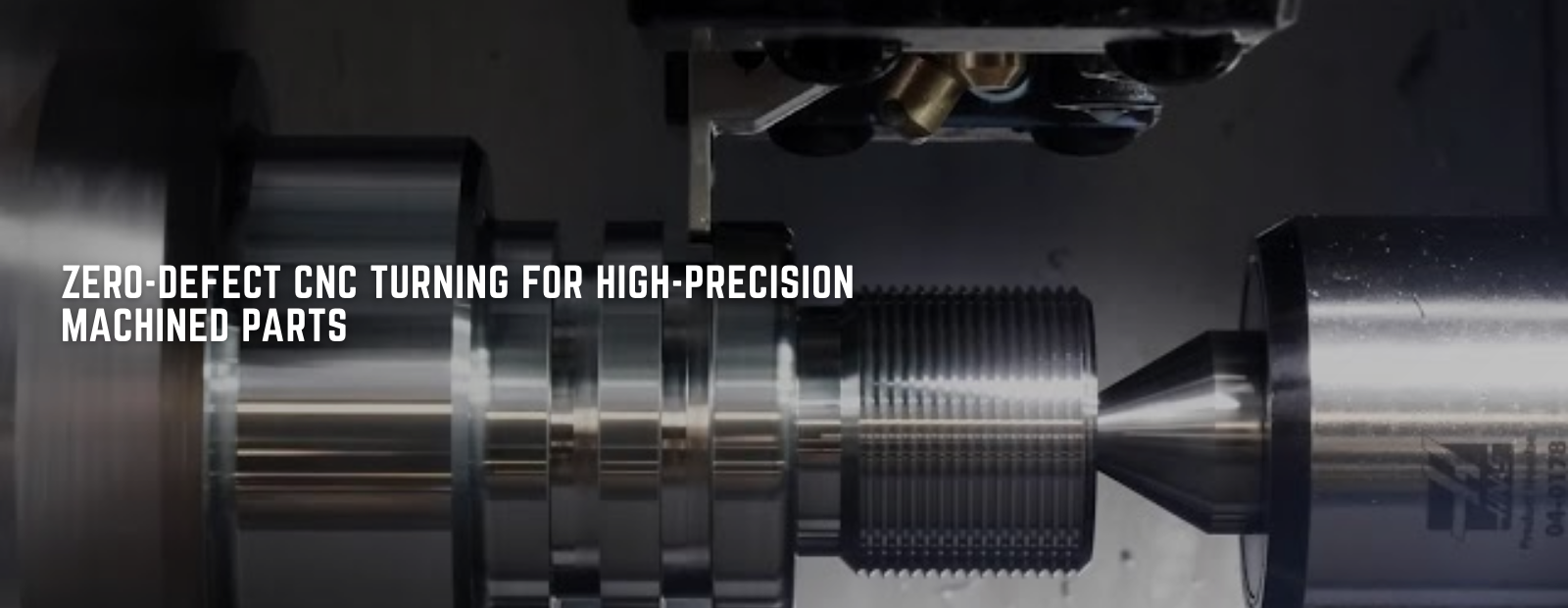

Innovative Solutions

We prioritize precision—meeting GD&T requirements, maintaining repeatability, achieving form errors under 10–15 μm, and producing surface finishes as refined as Ra 0.2 μm.

- CNC MACHINING

- CNC TURNING

- PRECISION GRINDING

- MATERIAL WE PROCESS

- ASSEMBLIES AND SUB-ASSEMBLIES

- VALUE ADDED SERVICES

Get In Touch With Us Today

Learn More From

Frequently Asked Questions

We provide multidisciplinary services including Manufacturing of precision mechanical components & assemblies, concept models, concept modeling, detail design, project management, and supply chain management.

Our experienced team follows a structured project management approach, ensuring quality, timely delivery, and effective communication throughout the project lifecycle.

Apexline is certified to industry-leading standards, including ISO 9001:2015 and AS9100D, ensuring that all products meet stringent aerospace quality and safety requirements.

Yes, Apexline offers tailored wear and material handling solutions designed to meet the unique challenges of aerospace environments, enhancing durability, safety, and operational efficiency.